Our Service

Ancillary Services

Electronics assembly was traditionally labor-intensive. These days everything except specialty circuits can be fabricated all or mostly by machine, making most circuit assemblies much more economical to build. But in those special cases when you need precision handwork, there’s no substitute. And when you need it, EMS has it.

- Aqueous cleaning

- Cleanliness testing

- X-ray and optical inspection

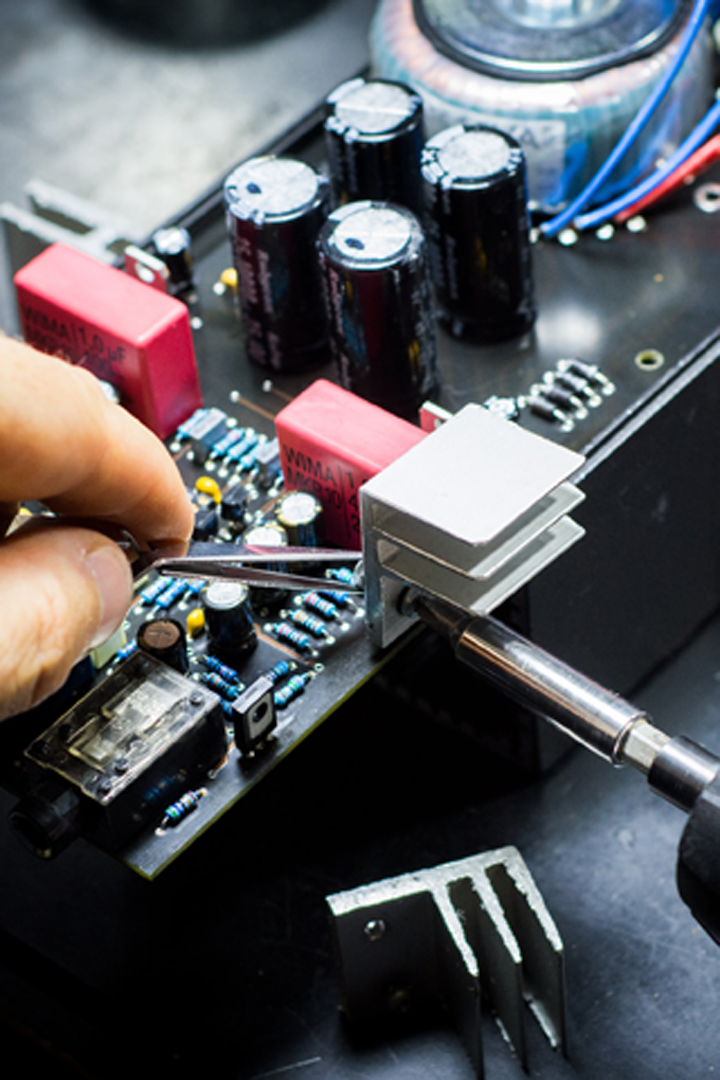

Precision handwork

If your application requires hand add parts or secondary operation. Our assembly technician team is ready to serve.

- Complex electro-optical or electro-mechanical assembly

- Custom modifications

- Circuit board repair

- BGA re-balling

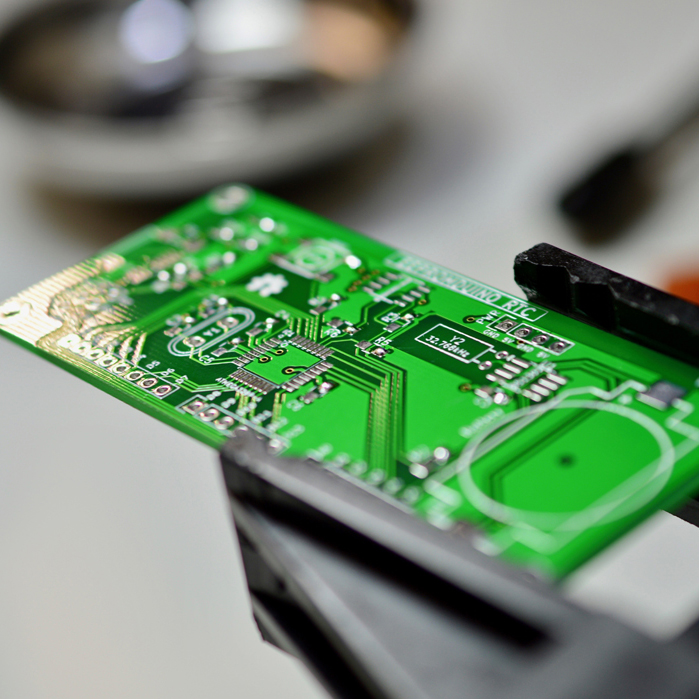

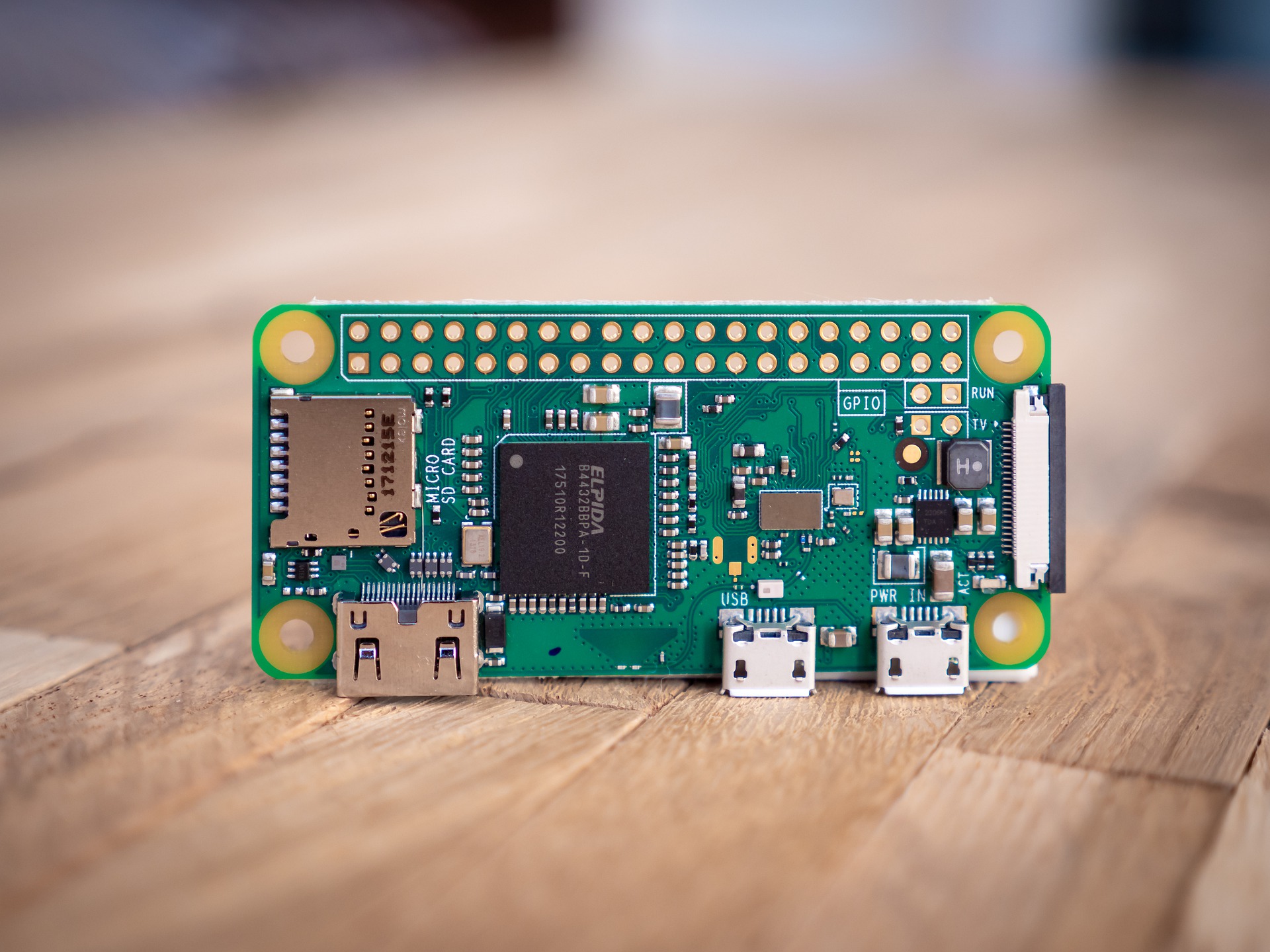

PCB assembly

Through-hole, surface mount or mixed technology ECB assembly

Leaded or lead-free soldering.

We are have integrated solutions for small prototypes to large production runs and hand assembly.

- Integration and packaging

- X-ray inspection

- SMT down to 0201

- Aqueous cleaning

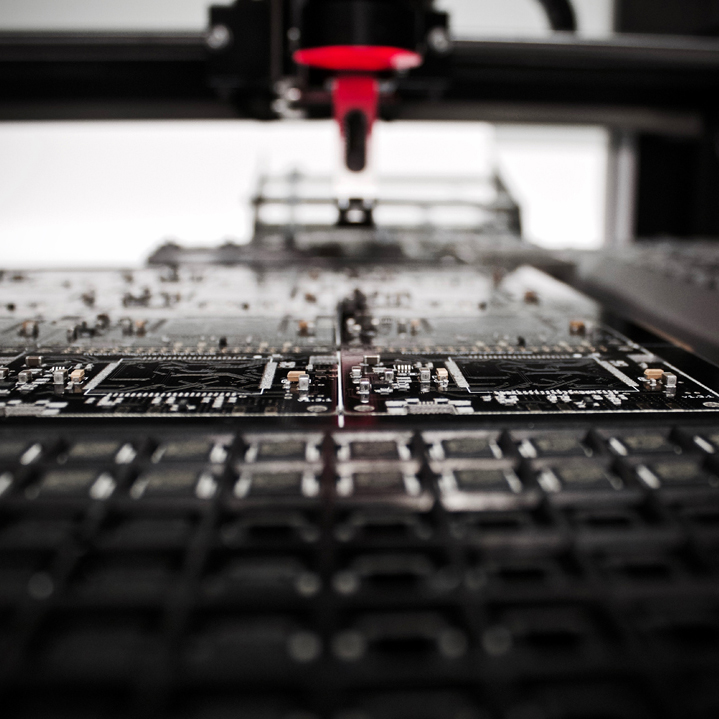

Automated assembly

All the usual stuff. We grew up on thru-hole, don’t have anything against it, and kept the tooling. But we have moved on with the times. High-density surface mount is the future and EMS is along for the ride. We can place passives as small as 0201 and pretty much any IC package.

And for those parts that can’t be reflowed, it’s a quick run through the solder wave.

- SMT, Through Hole or Mixed

- Hand placement and hand soldering

- Lead or RoHS soldering

- No-clean fluxed process available for non-washable parts